A timeline of ZP history in the reduction of greenhouse gas emissions

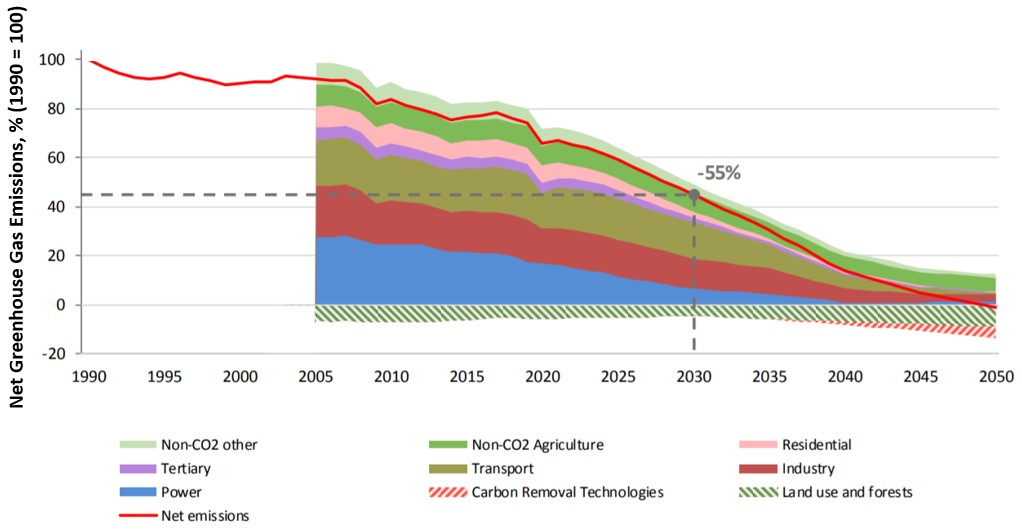

Last December the European Council agreed to reduce the net greenhouse gas emissions of at least 55% by 2030 in respect to 1990, thus to enhance the previous goal to drop emissions by 40% during the same time frame.

This new challenge follows the wake of the European Green Deal, it is coherent with the Paris Agreement adopted in 2015, and continues the previous initiative, which was successfully accomplished, of a reduction of greenhouse gas emissions of 20% in 2020 always in respect to 1990.

Thus, 1990 is a significant year for European climate policies, representing a benchmark for the definition of the milestones along the virtuous pathway towards a climate neutral EU in 2050.

Therefore, for the first issue of the Green Corner, we decided to compare the present and the past, looking precisely at our last 30 years of operations, in order to illustrate how the production of our parent company Zeleziarne Podbrezova a.s (ZP) has evolved from 1990 to the present day.

It seemed in fact right to us to start this innovative editorial journey from the past, to show what has already been done and transparently describe the efforts made and the results achieved so far.

Figure 1: EU’s pathway towards climate neutrality by 2050 – Brussels, 17.9.2020 – COM/2020/562 final

In 1990, ZP produced around 287.000 tons of steel divided between billets and seamless pipes. At the time, the production process was based on two small Electric Arc Furnaces (EAF) and three open-heart furnaces, also known as Martin-Siemens furnaces, that were fuelled by heavy fuel oil. The steelmaking and the pipe mills operations were resulting in about 195.000 tons of CO2 direct emissions.

In the same year, ZP started the modernization of its production plants, especially by building a large 60-ton Electric Arc Furnace, the construction of which was positively completed in 1993. This important investment thus led to the total substitution of the small EAFs and the Martin-Siemens furnaces. The production capacity of the new Electric Arc Furnace that was originally planned to be 220.000 steel tons per year, progressively increased to 380.000 steel tons thanks to a continuous work for performance improvement.

In the years that followed the realization of the new plant, ZP carried out numerous other investments in order to increase productivity, maximizing the processes’ energy efficiency while minimizing their environmental impact.

Among the numerous investments, we wish to list the most important ones: the reconstruction of the rotary-hearth furnace of the tube rolling mill (1997); the installation of an high-efficiency cogeneration unit, for the simultaneous production of electricity and steam (2001); the reconstruction of two tundish preheating stations of the continuous casting (2002); the renovation of the walking-beam furnace of the rolling mill with the introduction of regenerative burners (2004); the important upgrading of the heat treatment furnaces (2004-2007); the upgrading of the elbows production plant with induction furnaces (2007-2008); the installation of three oxy-fuel burners in the Electric Arc Furnace (2007); the construction of a new continuous casting (2013); the construction of a new Electric Arc Furnace dedusting plant provided with waste heat recovery system (2013); the renovation of company’s buildings for energy saving (1996-2016).

The aforementioned investments, carried out from 1990 to today, amount to over EURO 66 million. A substantial economic effort that resulted in 2019 in a production of 327.000 tons of steel, in the form of billets, seamless pipes and elbows, and 94.000 tons of CO2 direct emissions. Overall, between 1990 and 2019, ZP increased its production by 14% while reducing its direct emissions by 52%, and the specific emissions per unit of steel by 58%.

Therefore, thanks to the actions taken in the past, ZP is today a steel producer that bases its production on the recovery of ferrous scrap through the electric steelmaking, coherently with the virtuous objectives of a circular economy set by our society, taking moreover advantage of the Slovak electricity mix, among the less carbon intensive in the European context.

The investments made in the last thirty years allow ZP to be among the most important European producers of seamless tubes with a 10% market share for both hot rolled and cold drawn tubes, thanks to its efficient rolling process, 23 drawing branches and 7 heat treatment furnaces.

But above all ZP and the Group it chairs count more than 3000 employees who have been able to build a professional and modern organization over the last three decades, devoted to the pursuit of quality and product’s competitiveness, while taking into account what nowadays we would call economic, social and environmental sustainability principles.

In conclusion, ZP’s efforts in order to continuously evolve and improve its processes, formally adopting an internal environmental policy since 1999, proved to be visionary and represent not only a confirmation of the choices taken in the past but also an incentive to continue with the same approach in the future.

Article written by:

lorefici@pipex.it

For more information, details or requests, don’t hesitate to contact the authors of this article.

Don’t miss out on our news and initiatives, read our BLOG and Subscribe to our Newsletter

Article published on 30/04/2021

infopipex@pipex.it

infopipex@pipex.it